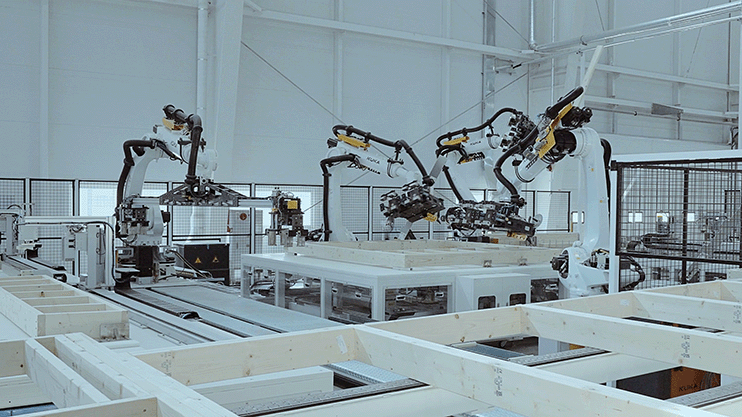

공정 레이아웃

Process Overview

This project involved the introduction of automated loading/unloading to ensure uniform heat treatment of the carrier mid-planet, a key component of automotive transmissions. The client implemented automation to address several issues arising from the previously manual process, particularly the increased defect rate and inefficiencies caused by workers. Hyundai Robotics' HH050 six-axis industrial robot was utilized for this purpose, automating various tasks such as product stacking, pin insertion, and tray placement, ensuring high productivity and stability.

Warranty Period

- 1 Year

Performance Year

- 2024

Project Duration

- 3 Months

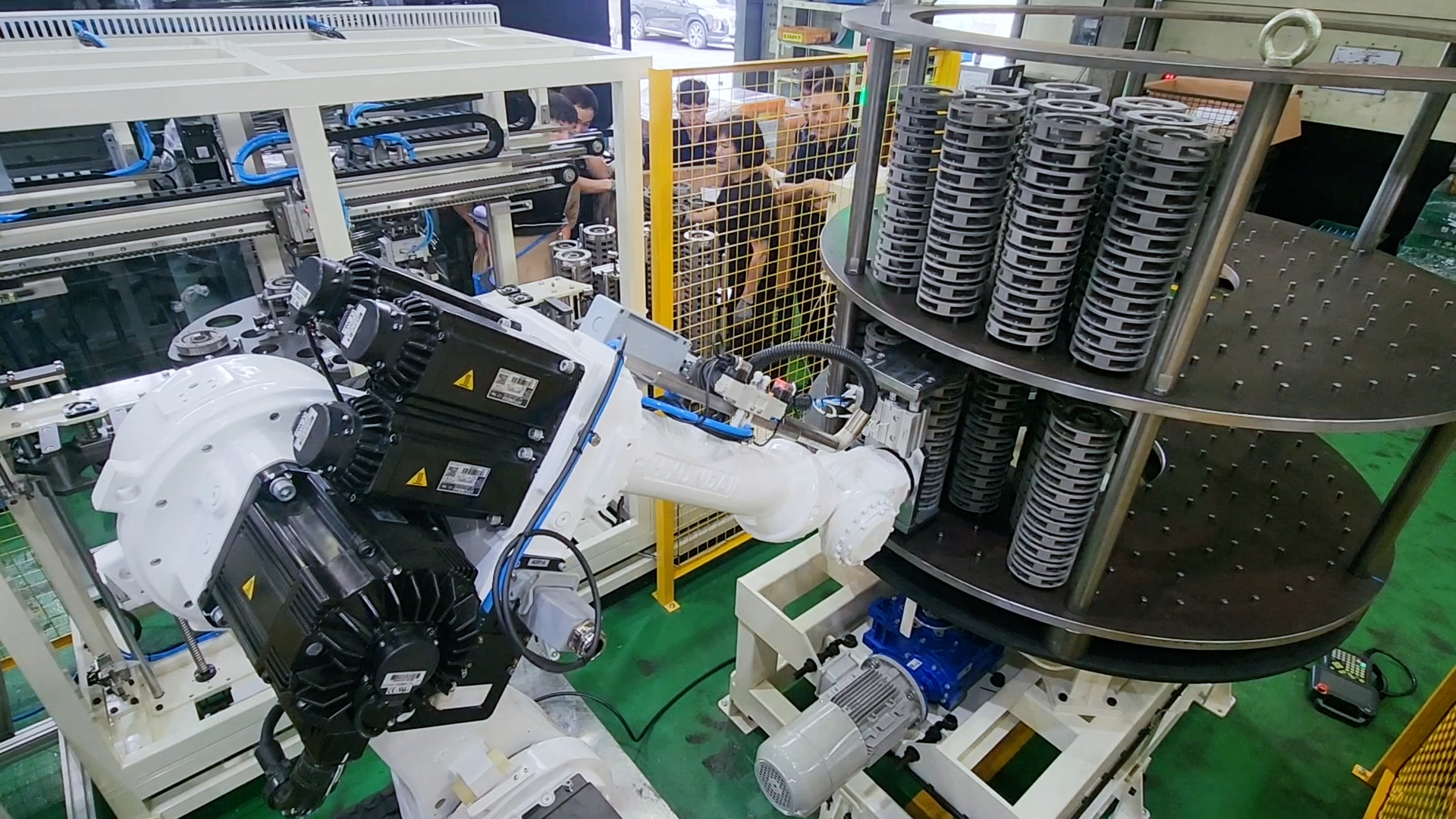

구성요소

| 로봇 | Hyundai Robotics' HH050 six-axis industrial robot ; |

|---|

작업순서

| STEP 1. | Product loading part: Manually place the mid-planet on the loading jig, and place 20 products per jig on the 8-segment index table to secure up to 160 product cartridges. |

|---|---|

| STEP 2. | Pin insertion part: The pins for loading are supplied and aligned through the parts feeder and placed on the mid-planet using a single-axis robot + air chuck combination. |

| STEP 3. | Loading part: Loading the mid-planet with the pin inserted, and use the servo-type to precisely control the position of the mid-planet according to its thickness. 2 sets are applied to prevent bottlenecks from occurring even when the laminated product is being discharged. |

| STEP 4. | Tray placement part: Using a 6-axis industrial robot, the loaded products are placed on a tray dedicated to heat treatment, 9 sets of fully loaded products are placed every 60' radius, and when the 360' work is completed, the worker uses a hoist to eject them with the tray, completing one cycle. |

특장점

Securing customer-specific layouts, fully automating pin inserts and loading operations, and securing a fast and stable production capacity of 720 pieces per hour.

도입효과

| 도입기업 피드백 | By automating the process, we were able to reliably produce 720 products per hour, significantly improving overall work speed and productivity compared to manual labor. By allowing robots to handle the repeatability and precision of the work, we significantly reduced the defect rate and minimized errors. |

|---|

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.