공정 레이아웃

Process Overview

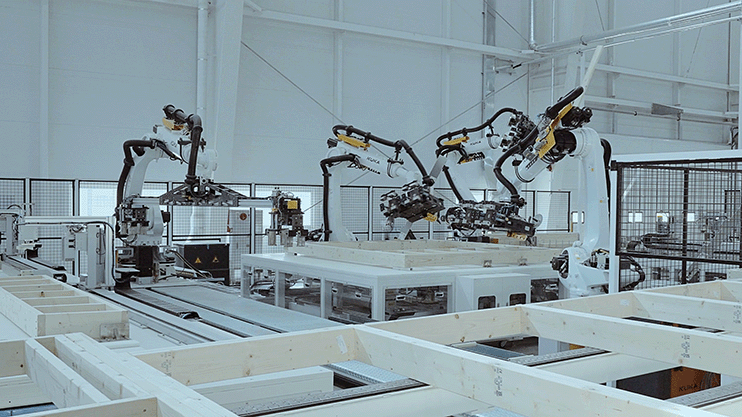

Bigwave Robotics (Marosol) established an automated assembly line for console parts for Kia Motors' newly launched SUV-type electric vehicle.

The existing console assembly line is a large-scale assembly line, requiring an average of 40-60 workers to assemble manually. The lack of automation experience presented challenges in securing space and recruiting assembly workers.

Frequent staff turnover and resulting skill level issues hindered productivity. To address this, the company replaced some workers with robots, addressing the labor shortage and consistently ensuring productivity by adapting to the changing workforce.

Warranty Period

- 1 Year

Performance Year

- 2024

Project Duration

- 4 Months

Project Background and Objectives

- Building a multi-product automated production line and reducing labor costs through robotic automation

- Preventing mis-assembly and mis-assembly using a lot-of-lot system and ensuring traceability

- Remote control and integrated management using SOLlink

구성요소

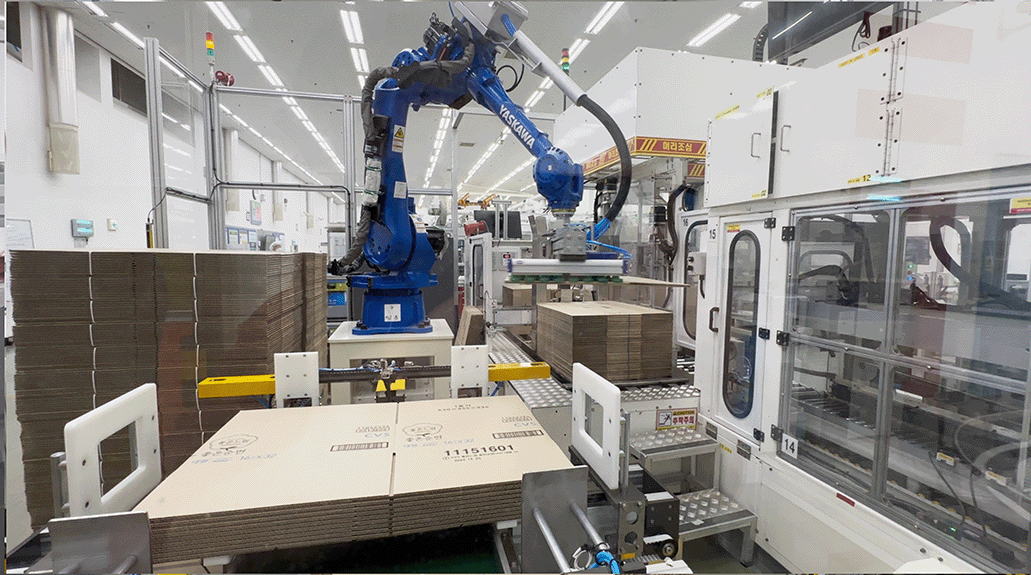

| 로봇 | The line utilizes Seiko EPSON's LS-b series, a proven product that has held the number one global market share in SCARA robots for 12 consecutive years, and the C series industrial robot.

The LS-b series boasts specifications ranging from a payload of 3 to 20 kg, a repeatability accuracy of ±0.02 mm, and a standard cycle time of 0.4 seconds. EPSON specializes in small robots, focusing on high-speed, high-precision, and low-vibration performance. |

|---|

작업순서

| STEP 1. | The new console parts for SUV-type electric vehicles are largely divided into three parts, each operated on a separate production line. The daily production volume for each line is recorded using the LOT system, with the vehicle type and quantity entered. Based on this data, each product is assigned a number and then production is conducted. |

|---|---|

| STEP 2. | The parts that go into each product are set up on the equipment by the worker, and the part information is linked to the LOT system through a barcode to manage inspection of different parts and missing parts. In normal operation, the robot fastens and assembles the product. |

| STEP 3. | The first line is a flow production line utilizing a conveyor, and the production parts include a wireless charger, a cup holder, and a tray for storing luggage. Due to the nature of the product, it is large in size and the fastening location is at the rear, so it was built as a conveyor type line to simultaneously secure operator operability. |

| STEP 4. | The second line is a standalone modular line, which is the largest part of the console parts, corresponding to the body. Since the assembly section is very small compared to its size, it is a line that is operated as a single unit. |

| STEP 5. | The third line assembles the parts that serve as pillars for the console, which is where the most parts are assembled. Unlike the two products above, this line combines three parts into one instead of assembling one part. Since the assembly time and method for each assembly section vary depending on the vehicle option, the equipment was implemented with a modular concept rather than a conveyor type. As products move through each process, the data is tracked and assembled using LOT barcodes to prevent heterogeneous product assembly. Since there are many product assembly sections, this is the section with the most robots. While other lines only perform vertical fastening, the third line also performs lateral fastening, so it also uses the C series, a multi-joint robot. |

특장점

Excellent maintenance and increased management efficiency.

- First, SOLlink is used to identify the current status of the robot and the production flow. This allows for the identification of the cause and corrective action. If the initial solution fails, a second step is to utilize a SI partner located near the customer for rapid on-site action.

- SOLlink allows for increased management efficiency by monitoring workload, production flow, and robot status (errors and malfunctions), while the main controller provides integrated control.

Excellent space utilization and labor cost reduction.

- By presenting compact robots, equipment, and scenario concepts, the company streamlined its space by enabling the production of three products in the same space as a typical customer would need for one.

- The existing manual console assembly line typically requires 40-60 workers, but robot automation allows for production with fewer than 40 workers.

Simplified work processes.

- The LOT system prevents mismatches and misassembly, while the traceability system simplifies work processes at the main controller.

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.