공정 레이아웃

This solution automates the repalletizing process for Atlas batteries produced by Hankook & Company for export. Due to the diverse import pallet specifications, customer-specific palletizing patterns, and product types, the total number of possible scenarios exceeds 200. The goal is to standardize these scenarios and ensure line stability by supporting a throughput of 10 pallets per minute for medium-sized batteries and 6 pallets per minute for large-sized batteries.

[Pallet Feeder & Pallet Conveyor]

- This solution allows for the use of up to five different pallet types per country, ensuring a smooth 10-stack logistics cycle. Destacked pallets are transported to the battery palletizing position and aligned simultaneously. Completed pallets are transported to the discharge position.

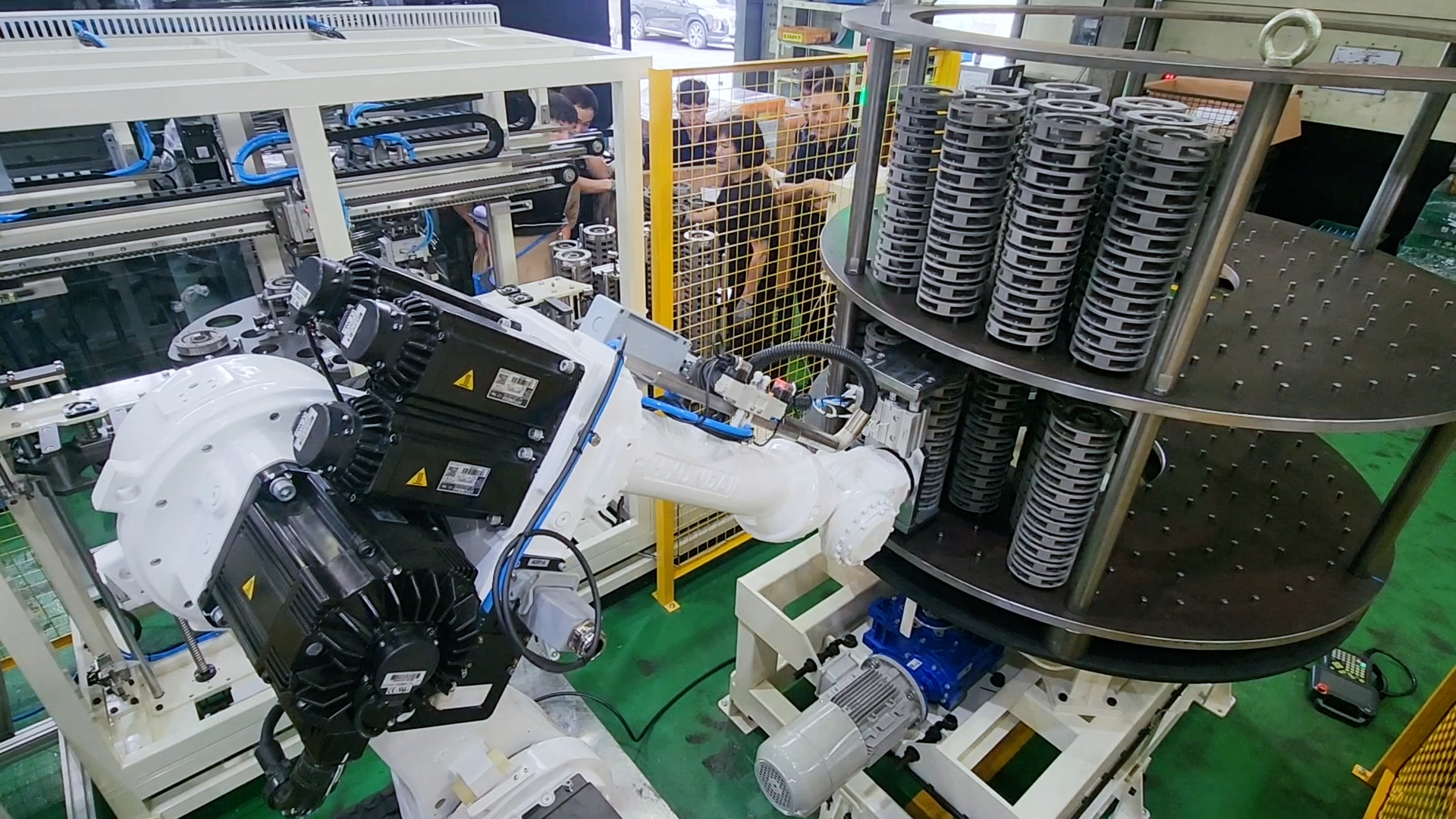

[Battery Sorter]

- Batteries fed inline are automatically sorted into 1st, 2nd (series/parallel), and 3rd layers according to the preset palletizing pattern. The robot then discharges the batteries, repeating the initialization process.

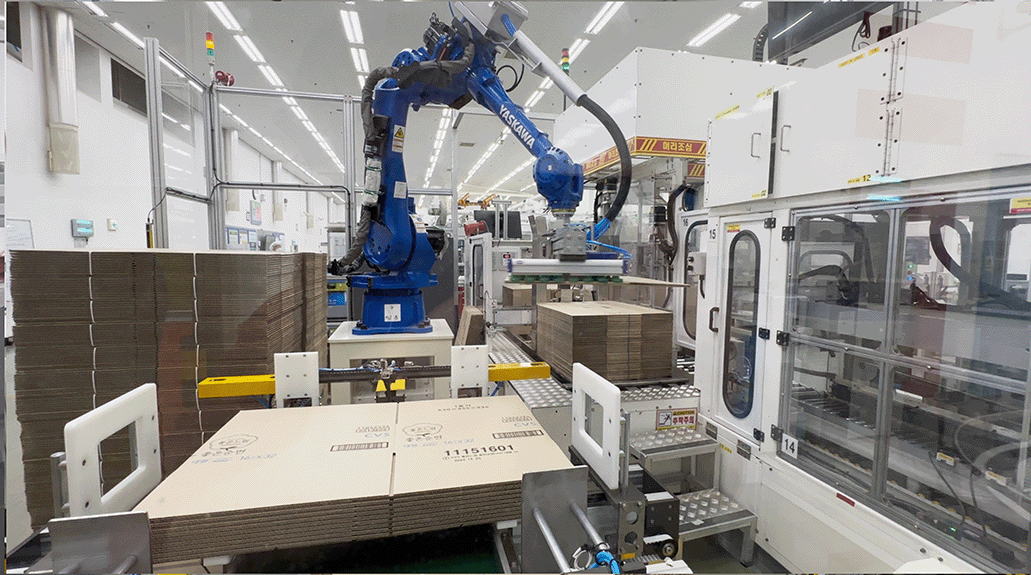

[Robot Palletizer]

- Once aligned, the batteries are picked and placed at the palletizing position on the conveyor, repeating the pick-and-place process according to the specified location and number of layers. Honeycomb feeds are automatically inserted into each layer according to the settings.

[Honeycomb Feeder & Sorter]

- Automatically sorts and inserts honeycombs into each layer of NO-BOX batteries.

구성요소

| 로봇 | YASKAWA GP225 |

|---|

작업순서

| STEP 1. | Pallet Feeder & Pallet Conveyor |

|---|---|

| STEP 2. | Battery Sorter |

| STEP 3. | Robot Palletizer |

| STEP 4. | Honeycomb Feeder & Sorter |

특장점

- Standardized palletizing for various pallets, patterns, and products.

- Secured daily palletizing capacity of 2,000 large and 4,000 medium-sized pallets, based on a 10-hour daily operation and an 85% safety margin.

- Reduced the number of workers per line from 4 to 1.

- Operator training, manuals, BOM lists, and spare parts lists were created and distributed. Video materials were secured for manager reference. Emergency response was provided in the event of a line shutdown.

도입효과

| 도입기업 피드백 | Palletizing batteries weighing up to 60 kg by hand by four people was a highly shunned task due to the risk of musculoskeletal disorders and even fatalities in the event of a fall. Even with four people working, the logistics cycle was not smooth, resulting in significant labor costs. However, after automating palletizing with Marosol, we were able to reduce the number of workers per line from four to one, ensuring safer work. |

|---|

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.