공정 레이아웃

Process Overview

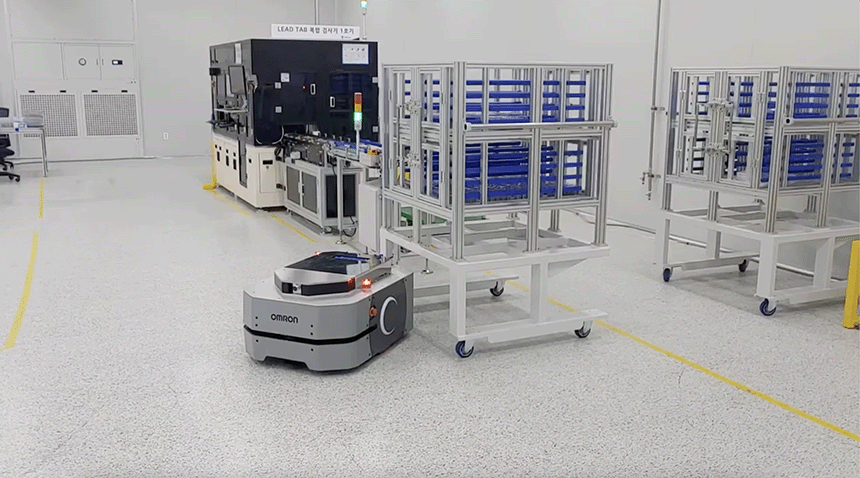

This case study demonstrates the automation of heavy-duty product transport using Omron AMR logistics robots.

The client implemented a logistics automation system to reduce inefficiencies and labor burdens associated with repetitive, heavy logistics tasks. Specifically, they sought to reduce costs and maximize logistics efficiency through automated palletizing and return operations.

This solution automates simple, repetitive tasks like product movement and loading, thereby increasing the efficiency and accuracy of the shipping process and reducing worker burden, thereby enhancing safety and productivity.

Project Background and Objectives

The client recognized the need for automation in heavy cart transport and lead tab return operations and sought to improve logistics operational efficiency and reduce operating costs by introducing AMRs.

This project aimed to:

- Automating lead tab return and cart transport

- Improving worker productivity and ensuring safety

- Enhancing efficiency and flexibility in the logistics field

구성요소

| 로봇 | Omron AMR logistics robot LD-90: Moves autonomously while avoiding obstacles, equipped with a two-row conveyor, and loads and returns up to 6 lead tab trays. ; Omron AMR logistics robot LD-250: Equipped with a lift, transports up to 64 lead tab trays by combining with a cart, and moves autonomously to the destination after automatically recognizing the cart. |

|---|---|

| 주변기기 | Robot upper module: Customization for tasks is possible, and productivity is increased by automatically processing repetitive tasks. ; Robot station: Loads the cart to be transported by the robot to support stable logistics return. ; Composite inspection machine: Inspects the trays returned by the robot, and automatically detects defective products. ; Buffer conveyor: Loads the trays after inspection, and provides a buffer to help workers load the cart. ; Tray cart: Up to 64 trays can be loaded, and is transported by LD-250. |

작업순서

| STEP 1. | Calling the operator: Click the button → Receive command to move LD-90 → Autonomous driving to the designated location |

|---|---|

| STEP 2. | Tray loading: Manually load trays onto the LD-90 conveyor → Return to the composite inspection machine |

| STEP 3. | Inspection task: Inspector docking → Tray inspection → Buffer conveyor loading after inspection |

| STEP 4. | Cart loading: The worker manually loads the tray onto the cart. |

| STEP 5. | Cart transport: Call LD-250 → Cart automatically recognized and transported |

| STEP 6. | End of work: The robot automatically returns to the waiting area after work. |

특장점

Special Features

- 24-Hour Process Response: Even on sites with day-night shifts, robots can be alternately charged to ensure uninterrupted logistics transport.

- Separable Cart and AMR: Fully loaded carts can be stored at the station, allowing the AMR to perform additional tasks.

- Space-Efficient System: The AMR's various safety sensors allow for shared workspaces with workers, and an emergency stop button can be used to stop the AMR in an emergency.

- Easy Operation: Workers can call the robot by pressing a button installed on the production line or station, eliminating the need for complex operations. The robot then automatically performs the remaining operations, making it easy for anyone to operate.

Introduction Effects

- Increased Production Efficiency: Robots perform return tasks, reducing the time workers spend away from the production line and enhancing production efficiency.

- Cost Reduction: Automating logistics processes reduces labor costs by eliminating up to eight workers.

- Improved Safety: Autonomous driving automatically avoids hazardous situations, and emergency stop functions minimize the risk of accidents during operations.

- Optimized Logistics Tracking: A real-time logistics tracking system enables efficient management of product shipment status and location.

도입효과

| 주요지표 | This AMR automated lead tab return solution has demonstrated notable improvements in work efficiency, safety, and workforce management. Previously, each return process required two to three workers to manually transport trays. With the automated solution, operations can now be performed by just one worker, intermittently monitoring the robot, resulting in a labor savings of over 50%. Furthermore, return work time has been reduced by approximately 30%, improving production line efficiency. Furthermore, line outage time has been reduced by over 80%, allowing workers to focus on their core tasks. Most importantly, workplace safety has been significantly improved during the transport of heavy trays. Thanks to the autonomous robot's obstacle avoidance and emergency stop functions, zero accidents have occurred since its introduction. |

|---|---|

| 도입기업 피드백 | The client commented, "The introduction of AMR robots not only reduced worker input but also significantly improved logistics safety. In particular, the well-equipped automation system created an environment where workers could easily operate the robots and focus on their tasks." |

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.