공정 레이아웃

Process Overview

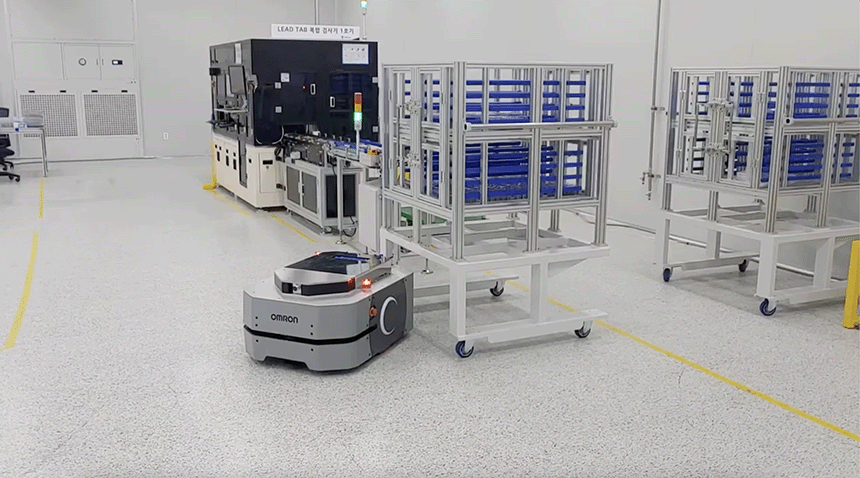

- This case study demonstrates an order picking system that optimizes the operation of ten Eugene Gocart 180s using Marosol's remote control system, SOLlink.

- With the self-developed SOLlink, multiple AMRs are clustered and controlled to maximize logistics system efficiency. The order picking system, integrated with WMS, allows for flexible handling during peak periods without the need for additional workers.

Warranty Period

- 1 Year

Performance Year

- 2023

Project Duration

- Need for consultation

Project Background and Objectives

- Improved workforce supply and employment stability through the introduction of logistics robots

- Introducing robots for high-intensity, repetitive tasks reduces the risk of musculoskeletal disorders and industrial accidents among workers

- Integrating WMS and order picking systems increases work efficiency and reduces error rates

구성요소

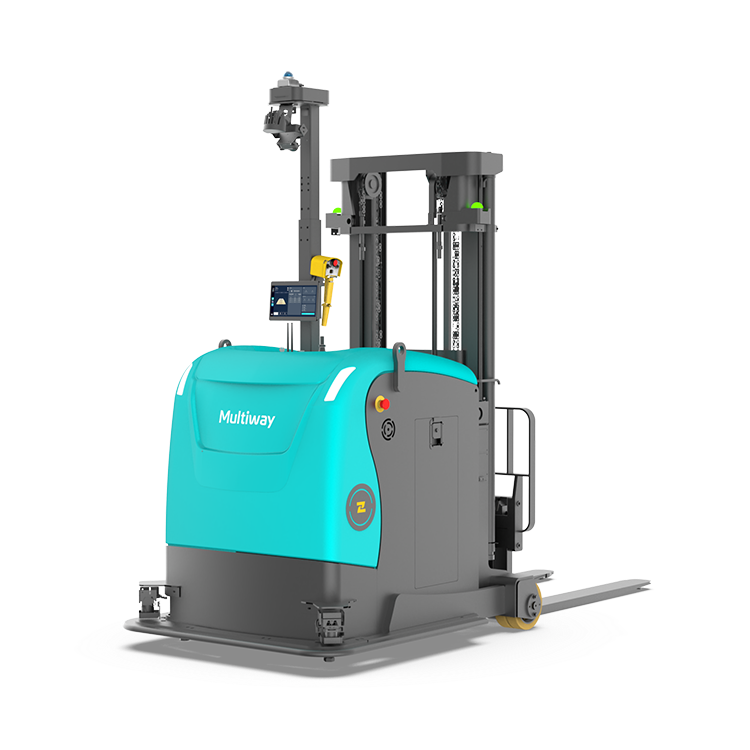

| 로봇 | Yujin Robot GoCart180 *10 |

|---|---|

| 주변기기 | Integrated multi-robot system SOLlink

Upper module

Order picking cart

Middleware |

작업순서

| STEP 1. | A worker positions himself between the racks in the warehouse |

|---|---|

| STEP 2. | AMR loads the cart |

| STEP 3. | AMR passes the rack and stops at a designated location |

| STEP 4. | The worker loads items onto the cart |

| STEP 5. | When the cart is full, the AMR unloads the cart at a designated location. |

특장점

- Connect to the entire conveyor line for high-capacity processing.

- The intuitive UX/UI of the OP panel allows for flexible support of various pallet/bag sizes.

- Using a product sorting device, a vision-free, low-cost solution is implemented.

도입효과

| 주요지표 | More than doubling the maximum daily order picking capacity per worker, expanding the use of robots in logistics warehouses, and reducing worker musculoskeletal disorders and turnover rates. |

|---|---|

| 도입기업 피드백 | The introduction of robots reduced workloads, leading to increased employee retention and a more flexible response to sudden increases in cargo volume. Notably, lower body fatigue was significantly reduced by eliminating the need to carry picked items. The logistics robot system, integrated with the upper-level WMS system, reduced human error and boosted customer satisfaction. |

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.